Cycling is an amazing activity. It is great for physical/mental health and fitness, a practical form of transportation, and a great sport (technically a whole family of bike-based sports). One thing to know is that aerodynamic drag is the primary force slowing down a cyclist. Meanwhile, a primary nuisance on the bike is getting covered in water, or worse mud, from wet and dirty roads. Fenders (also called mudguards, but I am going with fender as the term here) are major help in reducing dirt on the cyclist, but they tend to be designed like mini parachutes, adding a lot of aerodynamic drag, so you don’t see them as often. Always before this day you had a choice: fast and dirty or slow and (somewhat) clean. No longer, today, I bring you the freedom to be both fast and clean (mostly).

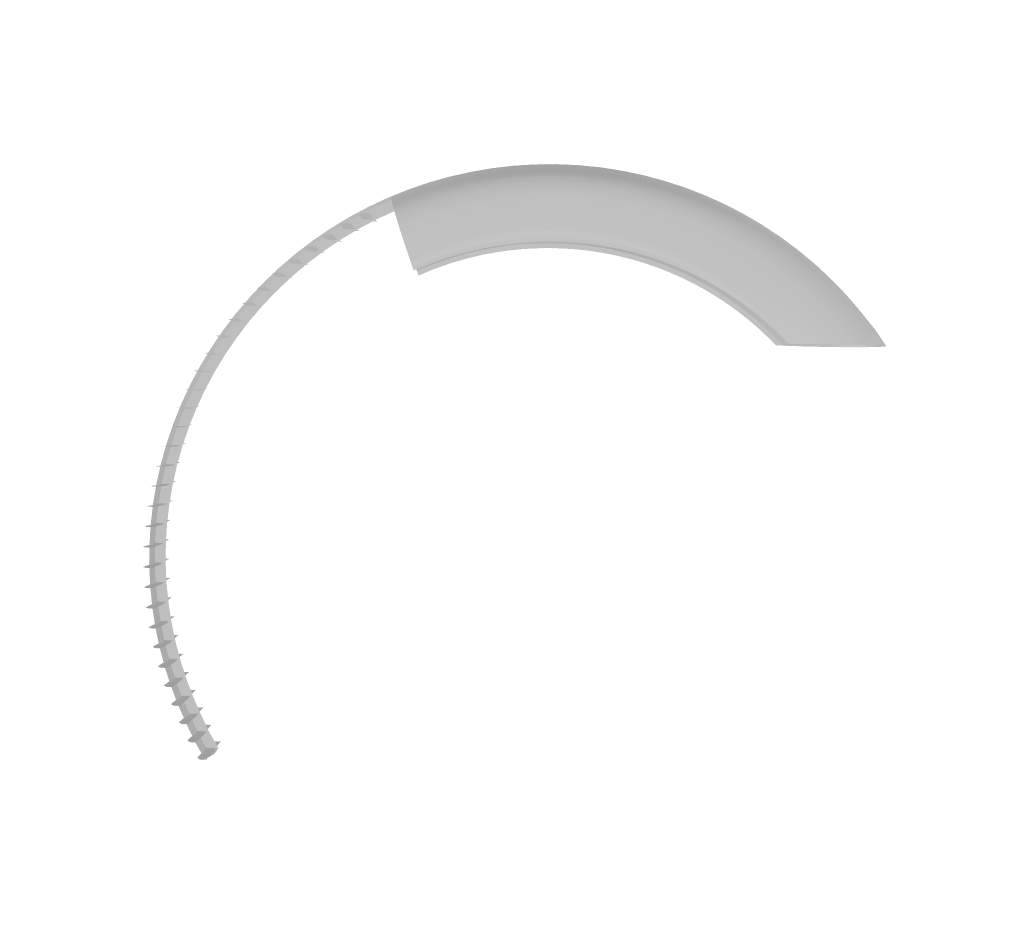

It has been known for a long time that fenders can be used to make a bicycle more aerodynamic, the concept can be see back to at least 1946. Because the top/return part of a wheel is moving twice as fast as the rest of the bicycle, and because drag increases quadratically with airspeed, and because the front wheel is a major part of the frontal area of a bicycle, there is plenty of savings to be found. However, it is only the top/front of the wheel that really sees the most advantage when covered by a fairing (as the return spinning part of the wheel is moving at the same speed as air, so adds little drag).

Note that many “aero” race bike frames “hug” the rear wheel to give the same aerodynamic drag benefit as a fender to the rear wheel, but they can’t do much for the more important front wheel drag.

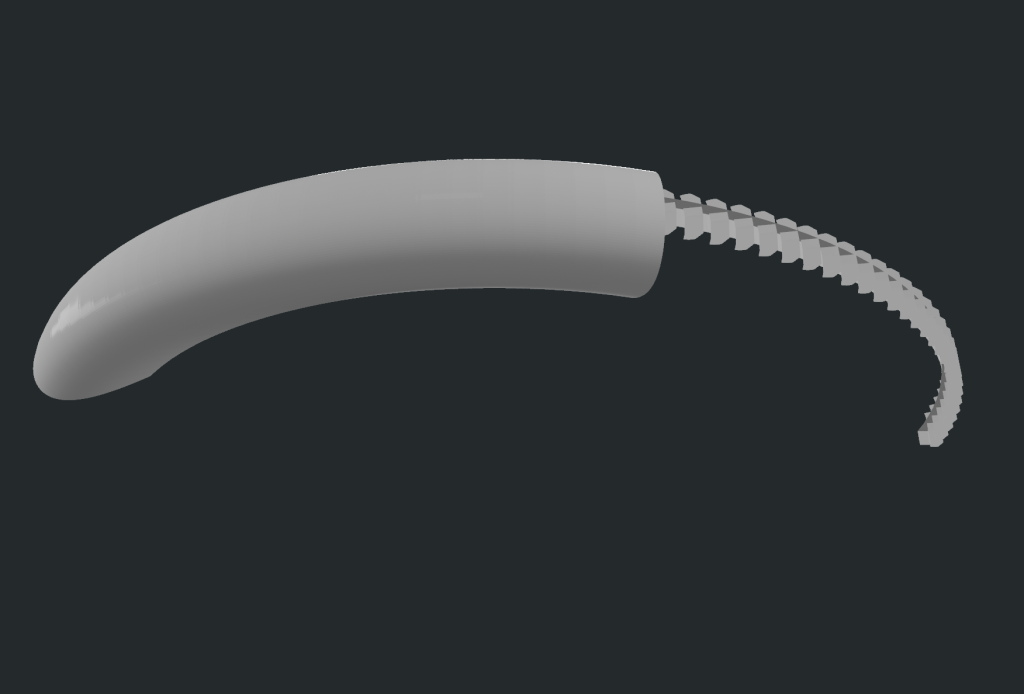

The challenge is that the part of a fender that is most necessary for controlling water/mud spray is the part that does not add aerodynamic improvement, it is the rear half of the wheel and adding a fender here significantly increases drag (bad). Diving into it, water spray leaves a wheel tangentially to the point where it loses contact with the tire, then transitions to a ballistic path (pulled down by gravity). If you have the fender close to the wheel, this means you can intercept the droplets of water when they are still effectively tangent to the circle, and, the big idea, you don’t need a full body mudguard for that. Instead, a stack of a large number of wings (louvers, like louvered window blinds) can intercept the spray and be much more aerodynamic, small wings have a tiny amount of drag compared to the “parachute” of a classic fender. In my design a “spine” goes into the aerodynamic shadow of the wheel for structure, and the wings extend out to the sides.

I felt extremely clever for coming up with this louver idea, but then I did some research and found several companies sell very similar concepts for truck mudflaps, one of them even stating their concept goes back to the 1980‘s and another being Michelin.

Probably the main reason we don’t see this style of fender yet for bicycles is the construction complexity. So my main contribution here is I wrote a Python script that can dynamically generate this fender design. Which is really cool! It can generate and resize the fender to any parameters easily. Want a mountain bike size instead of a road bicycle size? Just bump the tire size in the script and you are good to go (actually, some iteration is required to make sure you have the dimensions right for the bike, but that’s mostly real world measuring and testing, not extra design work).

It took me quite a while to make this code. Even in the AI-assisted coding era we have just entered, it took a lot of iteration from both myself and coding agents to get this working. This is really pushing to the frontiers of what can currently be done to generate 3d objects using code (without CAD), although I suspect this kind of work will become more common and better supported going forward (thanks to AI chatbots making approaching tasks via language and coding more automated than via GUIs).

I briefly thought about patenting this idea, until I turned up all the prior art (the 1940’s and 1980’s origins). Then I thought about trying to produce and sell this idea. And I probably could have done that. However, my thinking is that the “high performance” fender market is not that large, and if it were successful, since it cannot be patented, copycat versions would arise. As you may have noticed, my time is precious to me as I have a lot of things I want to work on, and the $/time of this just didn’t look like it would be worth it. Instead, I have open-sourced this idea under a copyleft open source license (see code).

I think this idea has a lot of potential, and can hopefully make cycling commuting even more practical, and that in turn is good for both people and the planet.

Construction

As I write this, work is not yet integrated on a bicycle, but here is the basic construction pattern:

- Run the script with the desired parameters. Carefully check all measurements!

- Have the resulting STL file 3d printed. A resin printer, using a heat resistant and impact resistant resin (like Somos Taurus) can do this, but it is not cheap to get large format items like this printed with high quality resins. A cheaper resin plus white spray paint (so it doesn’t heat up in the sun as much, off-white or light gray so it doesn’t show dirt as clearly) might work. Might require being split into two sections for injection molding.

- Mounting to the bike should be able to copy various mounting patterns for fenders. In fact, an existing fender can likely be scrapped for parts (that’s my plan). The main idea is usually an L-bracket holds the fender to a bolt point, with a clamped stainless steel rod providing rigidity on the tail section. I currently plan to attach the rods to the fender by manually reinforcing one of the wings with carbon fiber (raw roll, not prepreg) and epoxy, wrapping it around both rod and louver wing.

Some things to try:

- Increase the chord of the front airfoil section, easy enough in this script. This should have benefit like a deeper fairing wheel (but also more weight and cross wind wobble)

- For durability, increase louver thicknesses, but also increase chord to maintain aerodynamics.

- Improvement on drip control. Even with full fenders there is still “mist” spray (even with classic fenders). I suspect changing the geometry of the spine (slight inward curve, rounded edges), and perhaps some tweaks to the louver airfoils, could reduce spray further

- Use a hydrophilic coating on the spine (encourage water to flow down it) and a hydrophobic coating on the airfoil sections (to help keep them clean and free flowing)

- A rear fender is generally less sensitive to aerodynamics, being in more sheltered/disturbed airflow already. For many riders you only need the top part anyway, so just cutting down a standard fender is probably a decent option. A full fender is nice though if you plan to do winter group rides (the spray benefit being more for riders behind you).

Note I suspect this will be more vulnerable to mud build up than conventional fenders, we shall see. The target user is more “roadie with damp roads” than “off road bikepacker riding through monsoon season”.

Colin Catlin, 2026