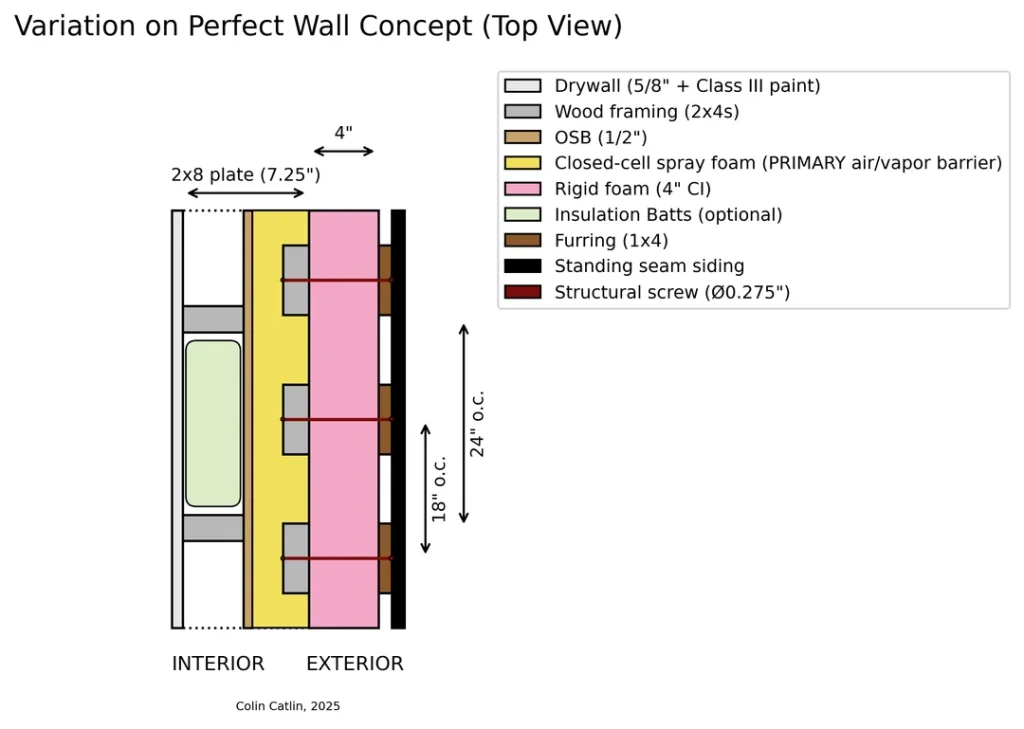

I have been agonizing over wall details to try and make the perfect (but practical) wall for a residential home that balances moisture (mold risk), thermal bridging, air tightness, and constructability.

Here is what I came up with, and got some feedback on reddit of. While I will probably not go with this detail (it is a little too complicated and I want simple), it might be good inspiration for those interested in passive house type builds as it should be workable.

So what am I trying to do?

- Exterior closed cell foam that is (nearly) continuous. That is quite hard to detail in anyway, since it needs support. Properly installed closed cell foam is pretty awesome (*some debate is present about this).

- Between the OSB, taping, and the closed cell foam, aiming for a combined air barrier that is very effective at keeping in moist air.

- Minimizes thermal bridging from the screws holding the furring strips. Stainless steel is usually better, but this way, much cheaper coated steel can be used if desired.

- Assembly should also be quite good at reducing noise levels

- Takes up less interior/on-foundation space than a traditional double stud wall.

- Studs are easily visible for fastening rigid insulation, saving time and tedium on rigid installation install.

- Uses standard materials in standard ways, just rearranged a little

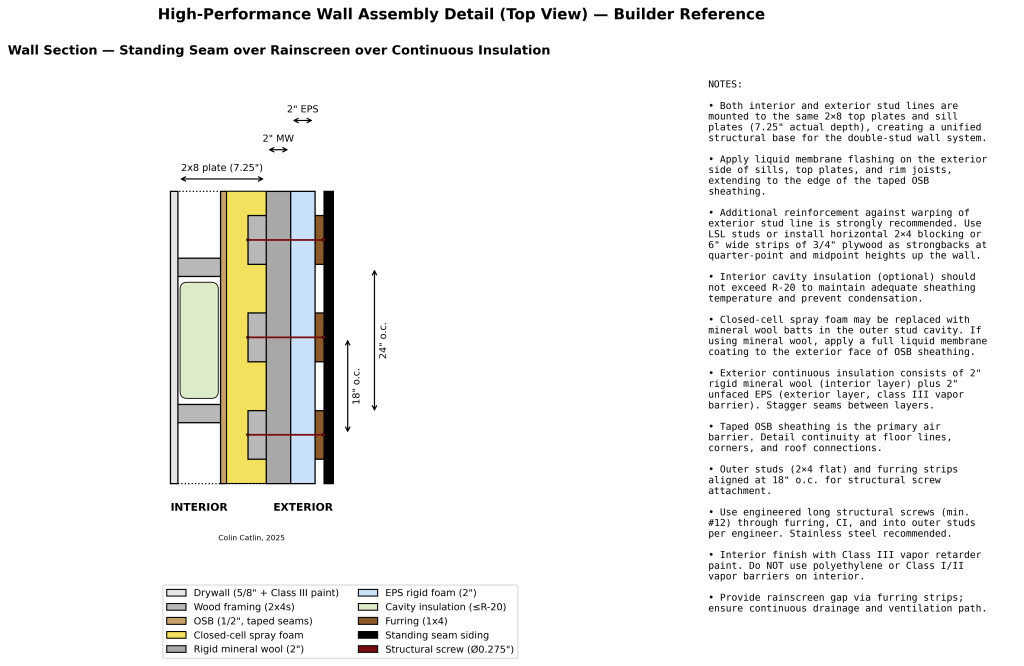

Challenges:

- New and unfamiliar (always faces lots of resistance in construction, not without reason)

- Exterior stud wall should drain outwards in mineral wool, but care must be taken warm moist air doesn’t linger on these studs (good air and vapor, obviously), and the unfaced EPS foam should keep rainscreen moisture from coming in too much. Be careful if switching foams, tape the EPS seams.

- Could be easy to forget to put liquid membrane on sill/plates/rim joist

Some other ideas for preventing beam warp on the front face (exterior stud line, which having its wide side used, risks having warping mess up the cladding). Generally, the foams should resist the warping to some degree. I am leaning towards favoring every other stud as an LSL.

- Using engineered 2x4s (LSL or LVL, more expensive)

- A “strongback” of plywood or 2x4s along either the back or front sides, horizontally across the studs (aluminum U-channel might work too)

- Quarter Sawn Lumber (very expensive unless milling your own)

- Carbon Fiber on both of the long faces (easier than it sounds, buy carbon fiber roll and epoxy on to both wide sides (not all four, so it can dry) with standard epoxy)

- Avoid: blocking between the stud and the osb behind (theoretically a strongly warping column could break the blocking out and thus break the vapor barrier)

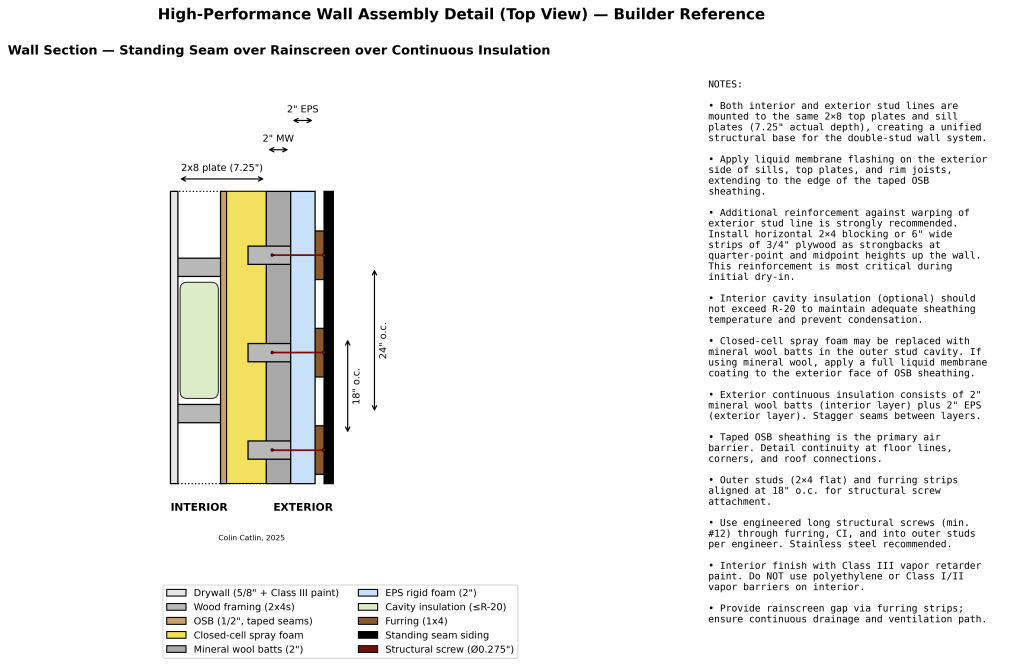

Possibly the exterior studs could be rotated out into the exterior space and provide structure for mineral wool batts (and also have more stiffness). Although as they would only be partly bearing on the plates, this might make some inspectors uncomfortable (code says 1.5″ bearing on wood, so should be fine, but that still expect discomfort). This version can also use cheaper mineral wool batts (cheaper than rigid mineral wool), and either increases the total foam insulation depth, or uses cheaper shorter screws and just keep the 2″ EPS (note that code requires I believe R-11 or R-15 continuous insulation in some places, so 2″ EPS might not be enough to pass). Standard blocking is straightforward on this, and recommended. And the people building it will probably complain because aligning the studs will require measuring a line down the plate, not just aligning to edge. I actually like this a little better than the first version, but I expect more pushback from both inspectors and contractors over it.

My original plan for full continuous closed cell foam was to glue XPS strips to the back of the furring strips, mount them, then spray between the gaps, so using a mix of XPS and closed cell foam. Still a valid idea, a bit labor intensive as well.

Oh, and I named it after myself, because why not? But actually wouldn’t surprise me if others have done something similar already.