While working on two multicopter drone related projects, I was distracted by the idea of an ultra endurance drone build, inspired by this discussion. There are really three steps to drone efficiency/endurance 1) keeping everything as light as possible 2) using high efficiency power regulators, motor controllers, and motors 3) highly efficient propellers (which is mostly aerodynamics). As I was working on other aerodynamics related projects, and also have always been curious about wind turbines, I decided to explore the propeller efficiency a bit more. So I ran my own tests which I will share, but first, some background.

There are quite a lot of variables at play here. Generally motors are most efficient at the higher, but not top, end of their range, and the same is true of voltage regulators (say 80%). Generally increasing voltage, and minimizing current, is more efficient in circuits. Both of these factors encourage higher voltage to the motor, which leads to higher RPMs. However propellers are generally more efficient at slower speeds, due to the basic fact that aerodynamic drag increases exponentially with velocity, which means lower RPMs is generally better for propeller efficiency. To try to close this gap, we go to lower KV rated motors, so we can more max out the voltage while keeping the RPMs lower.

Designing for efficiency, this means we generally want our expected “cruise” speed to be about 80% of maximums. In simple terms this means choosing high quality but undersized components in most cases (which also often saves weight another goal). The biggest tradeoff is acceleration and top speed. A drone designed for maximum efficiency is not going to be as good of a racing drone.

Electric motors (and electronics generally) are also more efficient when colder. Batteries are pickier about temperature, though.

Generally the rules of thumb for propellers are fewer blades (2 blade props) and longer propellers are the most efficient propellers.

The propellers themselves can have different airfoil designs, generally with the same set of tradeoffs. Propeller design is complex and there isn’t really a way to just look and see a prop’s efficiency. Here we mostly have to rely on marketing, most propellers advertise if they are “long range” or “endurance” designs, usually more efficient, or whether they are less efficiency focused, usually with labels focused more on “high thrust”, “high speed”, “great control”, and so on (although marketing may sometimes claim it is perfect at everything, which isn’t helpful because it can’t be true with the tradeoffs here). Crosswinds are also a potential factor.

One thing you can see is damage to a prop. Nicks and scratches in the blade can create some turbulent vortexes, and are therefore a bit less efficient. It is possible that small items on the blade (text is usually printed standing out on the blade) can be filed down and the blade polished for a small efficiency gain.

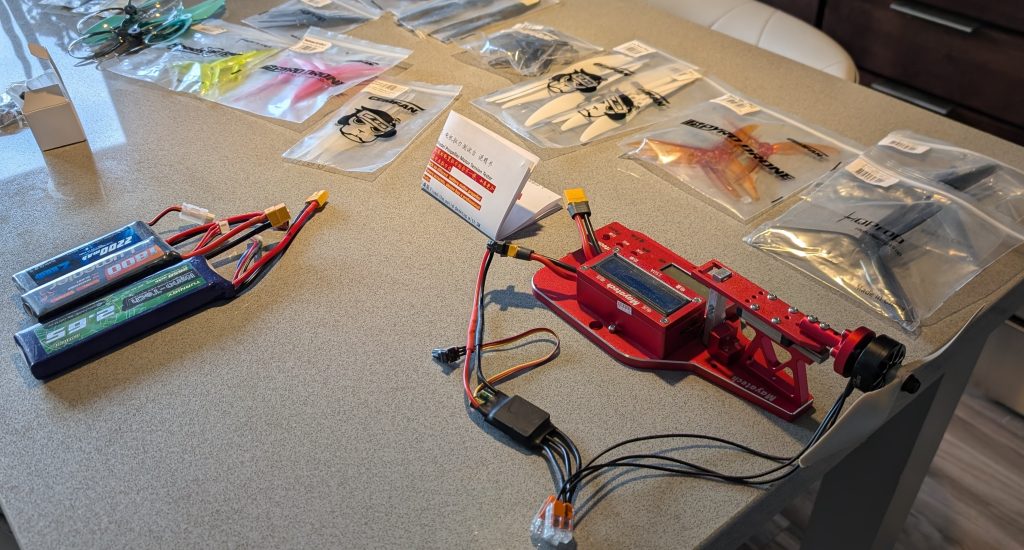

What really inspired this test was seeing a testing jig available for sale from Mayatech for $67. It is the heart of this test. It is really pretty straightforward. There is a load cell (the heart of any scale) pulled on by the motor, itself connected to a low friction rail. It has on/off oz/g and tare functions like most scales. A separate piece of electronics on the same block has an XT60 battery in and out which measures voltage, current, and watts. Connected to this I had a BLDC ESC I got off Amazon controlled by a potentiometer. This was nice in that I could easily adjust the output of the motor by turning the small knob. Finally I used the NIOSH SLM app on an iPhone 12 for the reading of sound levels at about 1 meter from the motor.

This worked pretty well, but my main frustration with this was the fluctuation in the readings (see in gif above). While I did my best to try and average numbers, it was very hard to pin down exactly what the average number was, my error here may have been as high as +/- 1 g/W. What I would highly recommend doing is connecting this to a raspberry pi type setup and being able to read and record the numbers on a computer, then average, which should be fairly easy for anyone who already have a bit of electronics experience (I’m fairly sure I could but I decided it wasn’t worth the time). This entire setup could actually be DIY’ed, although getting the rail and mount are probably worth the cost anyway to save some time. A second and easier to solve bit of error is likely in getting a higher quality ESC. This one worked fine, but I am guessing, being a random cheaper Amazon product, that much smoother numbers (and better efficiency) would be seen with a higher quality ESC. Many of these are programmable, and it would be straightforward for a professional to setup a closed loop system, where the ESC automatically spins up and stabilizes to a particular target thrust, then efficiency is recorded. I am drooling at the idea of the beautiful graphs that could be created, but it is probably overkill for any hobbyist.

Here I took measures aiming for around 62, 100, and 150 g of thrust. The main interest is 62 g of thrust, this being about what four motors each need to put out to lift a 250 g drone (the target max weight here). Note that the watts measured here reflects the sum of ESC losses, Motor losses, and Propeller thrust and losses, and indeed this setup could be used to test the efficiency of teach of these.

I largely ignored voltage here, but theoretically as the battery voltage falls, efficiency will increase a bit as the ESC will be closer to its more efficient level (higher throttle for same thrust). My assumption was this would be too small to be a major source of error. Along these same lines, my untested guess is that a 2S setup would generally be the most efficient practical battery cell choice.

Results:

- Larger propellers are generally more efficient (expected result!)

- Fewer blades tend to be more efficient (expected result!)

- Higher RPMs / Higher thrust on the same propeller is less efficient (expected result!)

- Visually similar propellers of the same model can have very different efficiencies (somewhat expected, very annoying!)

- Larger propellers are somewhat correlated with less noise, while at least in this test, more blades did not seem to make it much quieter

Two propellers here had interchangeable hubs that allowed them to used on either the small T-mount or 5 mm propellers, which is quite convenient for comparisons. I also had a 3d printed adapter that accomplished the same thing for the 8″ propellers, but it was rather a poor fit, and started wobbling, eventually spinning in place at higher speeds (temporarily solved by super glue on it). From this (Gemfan 5130) it can be seen that the Ummagawd Aerolite (UA) 2004 1600KV was a bit more efficient than the (much heavier) FPV King X2807-1300KV.

It is worth talking through the most frustrating result here. That would be Prop #1 of the Gemfan SL 6026. Multiple tests consistently showed it was significantly more efficient than two other propellers of the exact same model (one from a different order, one from the exact same bag so should be of the same batch). Visually they were the same, all propellers tested here were new. I had three possible explanations. Firstly, propeller balance. I don’t have a proper propeller balance, but testing more simply failed to show any clear difference. Secondly, defects of the blade shape or some defect on the blades. Not a great test, but comparing visually side by side didn’t yield any clear difference. Thirdly was stiffness. I could do a basic quantitative test by pressing the propeller against the scale to the same weight and then measuring the deflection. And this test did yield a clear result, significantly less deflection on the more efficient propeller. A possible explanation for the improvement is that it maintains its aerodynamic profile better than the others, which bend a bit into a less ideal shape at speed.

One conclusion here is that you could get significant efficiency improvement by testing all propellers and choosing the best. I am reminded of the world of shooting where different batches of bullets can vary widely in performance. This kind of optimization necessary for testing all batches ends up being a massive chore, and I really wish I could just buy the best model and not worry about it. Using carbon fiber propellers would likely reduce stiffness variation but could still have balance or defect issues.

Speaking of which, the 8″ blades were much quieter than the rest of the competition. Both were identical pitch (fairly steep), 8045, and both were high stiffness with carbon nylon or carbon fiber. In addition to the larger blades, I was wondering if the standoff of the t-mount to 5 mm adapter reduced noise, as it likely keeps the airflow a bit cleaner around the motor. Sound is more complex than this test accounts for however, as different propellers can produce different frequencies of sound, so some of the louder propellers were less annoying sounding than others. Still, the 8″ blades were the best both to the ear and to the microphone.

Yes, giant propellers should be fine on tiny motors when targeting efficiency, they just won’t be good for quick acceleration.

The donut propeller, a toiroidal style which supposedly is quieter and more efficient, was neither.

My biggest learning from this is perhaps how much a single propeller reduced in efficiency the higher the RPMs were. This was observed across both motors, and with it being ‘common knowledge’ that escs are most efficient near full throttle, it is most likely this is entirely due to the aerodynamics of the propeller. And this matches with our understanding of aerodynamic drag, the slower the tip speed, the less drag losses are. I was just surprised how big this difference was, a propeller at high rpms would easily be half of the efficiency of the same propeller at much lower speeds. Looking at other context, the first human powered helicopter, very high efficiency requirement, was a quadcopter and it was doing something like 10 RPMs (9.7 according to Google).

Conclusion: for efficiency, design the entire multicopter around minimizing RPMs at the needed flight speeds. Primarily this means larger rotor diameters. Lighter weight will also reduce the thrust required and therefore RPMs. A secondary optimization is to choose components with peak efficiency at this lower rpm level, undersizing generally which may also help lower weight. Choosing propellers like carbon fiber propellers and even going to the extent of testing each of these before flight will also help. In terms of actual brands of propeller tested, in this test the Gemfan SL 6026 has the best performance overall, but only in one of three propellers tested (the other propellers were good too, just not as good), while the carbon fiber 8045 is probably a more reliable bet for less tinkering.

Fixed wing is much more efficient than a quadcopter. This study was aimed at the quadcopter side of things but should generally be transferable to fixed wing prop as well. Aerodynamics matters more on a fixed wing, but also matters a bit for multicopters when not in a hover. Generally smaller and smoother shapes are better for aerodynamics.

It would also be worth studying what Ukraine is doing in their long range drones as they fight against the endless murders of Putin’s Russia, as there will be a lot of experience incorporated in those designs, but also more design constraints.

Full Results

| Propeller | Motor | Blade Number | Prop Weight (g) | Voltage | Watts | Thrust (g) | g/W | Decibels (~90 cm) | Notes |

| Gemfan 7050 | FPV King | 1 | 7.5 | 12.52 | 7.6 | 62 | 8.157894737 | 62.1 | |

| X2807-1300KV | 1 | 7.5 | 12.48 | 12.8 | 101 | 7.890625 | 66.8 | ||

| 1 | 7.5 | 12.48 | 23.4 | 155 | 6.623931624 | 72.8 | |||

| 2 | 7.6 | 12.48 | 14.4 | 101 | 7.013888889 | 67.8 | this prop has a few burrs, minor damage | ||

| Donut 5145 | FPVK | 1 | 4.5 | 12.45 | 11.4 | 65 | 5.701754386 | 70.1 | |

| 1 | 4.5 | 12.43 | 19.6 | 101 | 5.153061224 | ||||

| 2 | 4.1 | 12.43 | 20.4 | 100 | 4.901960784 | 76 | |||

| Gemfan 7035 | FPVK | 1 | 4.8 | 12.43 | 8.4 | 62 | 7.380952381 | 69.2 | this one appears to be an error |

| 1 | 4.8 | 12.4 | 13.5 | 103 | 7.62962963 | 74 | |||

| 1 | 4.8 | 12.36 | 20.3 | 152 | 7.487684729 | 77.4 | |||

| 2 | 4.3 | 12.36 | 12.6 | 103 | 8.174603175 | 73.2 | |||

| 3 | 4.6 | 12.34 | 12.3 | 100 | 8.130081301 | 73.3 | |||

| Gemfan D90 5R | FPVK | 1 | 3.7 | 12.33 | 14.8 | 62 | 4.189189189 | 68.7 | |

| 1 | 3.7 | 12.29 | 21.9 | 92 | 4.200913242 | 71.8 | *max of this propeller | ||

| Gemfan 5130 | FPVK | 1 | 3.4 | 12.29 | 10.9 | 62 | 5.688073394 | 72.3 | |

| 1 | 3.4 | 12.24 | 18.7 | 102 | 5.454545455 | 77.2 | |||

| 1 | 3.4 | 12.2 | 29.9 | 155 | 5.183946488 | 80.9 | |||

| 2 | 3.3 | 12.2 | 17.9 | 99 | 5.530726257 | 76.7 | |||

| Gemfan 5130 | Ummagawd | 1 | 3.4 | 12.24 | 9.6 | 64 | 6.666666667 | 72.5 | |

| Aerolite 2004 1600KV | 1 | 3.4 | 12.17 | 16.9 | 101 | 5.976331361 | 78.3 | ||

| 1 | 3.4 | 12.17 | 27.4 | 144 | 5.255474453 | 82.3 | |||

| Gemfan D90 5R | UA | 1 | 3.9 | 12.11 | 19.5 | 47 | 2.41025641 | 80.7 | mounted backwards, hence the problem |

| HQ T5X3 (2 blade) | UA | 1 | 2.4 | 12.11 | 8.3 | 64 | 7.710843373 | 75.7 | |

| 1 | 2.4 | 12.06 | 16 | 100 | 6.25 | 77.6 | |||

| 1 | 2.4 | 12.03 | 25.6 | 150 | 5.859375 | 80.1 | |||

| 2 | 2.6 | 11.9 | 8.3 | 60 | 7.228915663 | 73.3 | |||

| 2 | 2.6 | 11.9 | 15.7 | 101 | 6.433121019 | 78.1 | |||

| 2 | 2.6 | 11.9 | 26.9 | 150 | 5.576208178 | 81.7 | |||

| Gemfan SL 6026 | UA | 1 | 3.3 | 11.99 | 6.6 | 65 | 9.848484848 | 72 | |

| 1 | 3.3 | 11.99 | 11.6 | 98 | 8.448275862 | 75.5 | |||

| 1 | 3.3 | 11.97 | 22.5 | 151 | 6.711111111 | 80.3 | |||

| 2 | 3 | 11.87 | 7.4 | 62 | 8.378378378 | 72.1 | |||

| 2 | 3 | 11.85 | 13.4 | 101 | 7.537313433 | 79.4 | |||

| 3 | 3.2 | 11.85 | 7.5 | 61 | 8.133333333 | 72.2 | |||

| 3 | 3.2 | 11.84 | 13.8 | 103 | 7.463768116 | 78 | |||

| 3 | 3.2 | 12.59 | 7.4 | 62 | 8.378378378 | 72.4 | |||

| 3 | 3.2 | 12.57 | 13.3 | 99 | 7.443609023 | 82.2 | |||

| 1 | 3.3 | 12.57 | 5.7 | 57 | 10 | prop 1 is just an outlier, but it really looks the same | |||

| 1 | 3.3 | 12.56 | 6.5 | 61 | 9.384615385 | ||||

| 1 | 3.3 | 12.55 | 12.8 | 107 | 8.359375 | ||||

| 3 | 3.2 | 12.52 | 12.5 | 102 | 8.16 | ||||

| 4 | 3.1 | 14 | 106 | 7.571428571 | |||||

| 4 | 3.1 | 13.5 | 104 | 7.703703704 | polished with scotchbrite pad after previous | ||||

| HQ T6X2.5X3 | UA | 1 | 4.3 | 11.97 | 8.6 | 63 | 7.325581395 | 74.8 | motor cooled down from break between tests |

| 1 | 4.3 | 11.96 | 9.5 | 64 | 6.736842105 | 74.3 | |||

| 1 | 4.3 | 11.94 | 16 | 105 | 6.5625 | 79 | |||

| 1 | 4.3 | 11.9 | 26.9 | 155 | 5.762081784 | 82.2 | |||

| Gemfan SL5125-3 | UA | 1 | 3 | 11.9 | 8.5 | 63 | 7.411764706 | 73.2 | |

| 1 | 3 | 11.88 | 16.4 | 104 | 6.341463415 | 79 | |||

| 1 | 3 | 11.87 | 27.1 | 154 | 5.682656827 | 82.5 | |||

| HQ T3.5×2.5×3 | UA | 1 | 1.6 | 11.87 | 12.2 | 63 | 5.163934426 | 74.4 | |

| 1 | 1.6 | 11.87 | 22 | 103 | 4.681818182 | 78.5 | |||

| Gemfan 8045 | UA | 1 | 6.6 | 12.56 | 6.7 | 63 | 9.402985075 | 65 | |

| with 3d printed 5 mm adapter | 2 | 6.2 | 12.41 | 8.2 | 65 | 7.926829268 | 62.4 | ||

| 2 | 6.2 | 12.4 | 8.1 | 65 | 8.024691358 | 63.5 | |||

| 2 | 6.2 | 12.31 | 7.7 | 63 | 8.181818182 | 62.7 | |||

| 2 | 6.2 | 12.31 | 7.4 | 59 | 7.972972973 | 62.3 | |||

| 2 | 6.2 | 12.33 | 15.9 | 103 | 6.477987421 | 67.2 | |||

| 2 | 6.2 | 12.26 | 14.9 | 99 | 6.644295302 | 67 | |||

| 2 | 6.2 | 11.97 | 8.1 | 60 | 7.407407407 | engine running for longer time (10 min straight) before this series | |||

| 2 | 6.2 | 11.96 | 3.5 | 31 | 8.857142857 | * note the adapter had gotten a bit wobby here when done, so also a factor | |||

| 2 | 6.2 | 11.96 | 2.3 | 24 | 10.43478261 | ||||

| 2 | 6.2 | 11.96 | 1.6 | 19 | 11.875 | *this series I ran just to show how lowest power is most efficient | |||

| 8045 Carbon Fiber (generic) | 1 | 7.3 | 12.54 | 6.6 | 62 | 9.393939394 | 62 | ||

| with 3d printed 5 mm adapter | 1 | 7.3 | 12.4 | 100 | 8.064516129 | 66.5 | |||

| 1 | 7.3 | 8.8 | 80 | 9.090909091 | 64.1 | ||||

| 1 | 7.3 | 7.2 | 63 | 8.75 | 61.8 | ||||

| 1 | 7.3 | 10.2 | 82 | 8.039215686 | 64.8 | ||||

| 1 | 7.3 | 7.7 | 66 | 8.571428571 | 62.2 | note motor and base vibrations produce most of the noise here, propeller is very quiet |

This would probably make a decent school science fair project for anyone interested in drones. A few things other things to test: ducted propellers, different battery voltages, different motors, different ESCs, polished propellers, damaged propellers, and, of course, different propellers. Then run an endurance flight test on a quadcopter before and after optimizations. Make sure airflow obstructions around the test jig are consistent between tests. Run propeller up to speed a bit, turn off, recenter, tare, then do a proper test. One test I thought would be interesting was to glue a carbon fiber strip with epoxy to the trailing edge side of the propeller blades (part where air flow isn’t attached at high speed), rebalance, and see if the improved stiffness helped performance.

Colin Catlin, 2025